IoT R&D Center

OVERVIEW

In collaboration with manufacturing sites within Sumitomo Electric Groups, we promote manufacturing improvements using IoT(Internet of Things)/AI technologies such as various sensing methods, wireless communication and AI data analysis to deal with major production challenges: productivity improvement, automated inspection, predictive maintenance, and safety improvement. Our center works closely with the Production Engineering Department and the Information Systems Department to develop IoT/AI-based systems and train human resources.

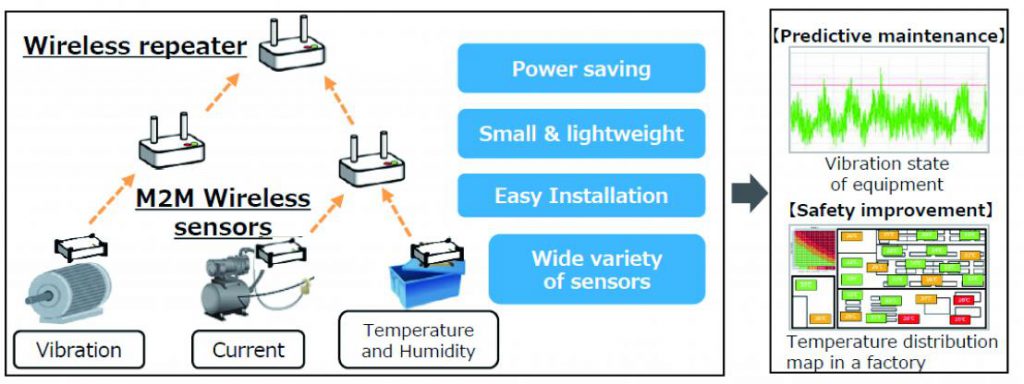

M2M Wireless Sensor

We develop battery-driven M2M wireless sensor to collect equipment data easily. The collected data is visualized by the IoT/AI platform system and can be used for various manufacturing improvements.

Visual Analyzer

There are two fundamental challenges in data collections on a factory floor. One is that old equipment often requires expensive modification. The other is the difficulty in collecting data regarding how workers move and operate on a factory floor. Visual Analyzer uses AI video analysis technology to extract and visualize operation information and stopping factors from camera images. For example, Visual Analyzer can automate time measurement for preparation-work to detect operation time-out and time-dispersion. For example, Visual Analyzer can automate the time measurement of setup work, detect excess work time and variation, and look back at those images to check the cause.

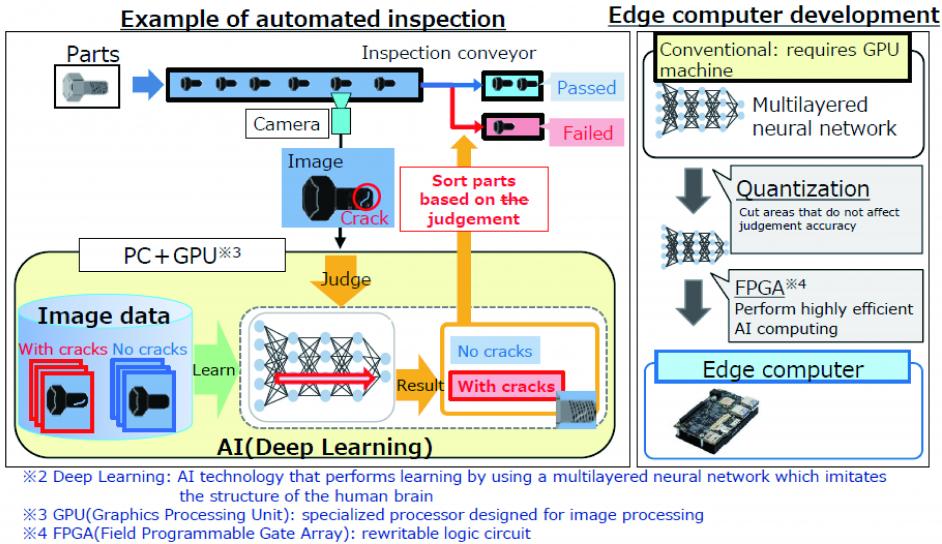

Automated AI Inspection

In many inspection processes, securing and developing human resources that perform visual inspection has been emerging as an issue. For that reason, we are working on automation of inspection processes using AI technology (Deep Learning *2). In addition, we are developing edge computers to reduce the cost and size of automated inspection systems.