Services

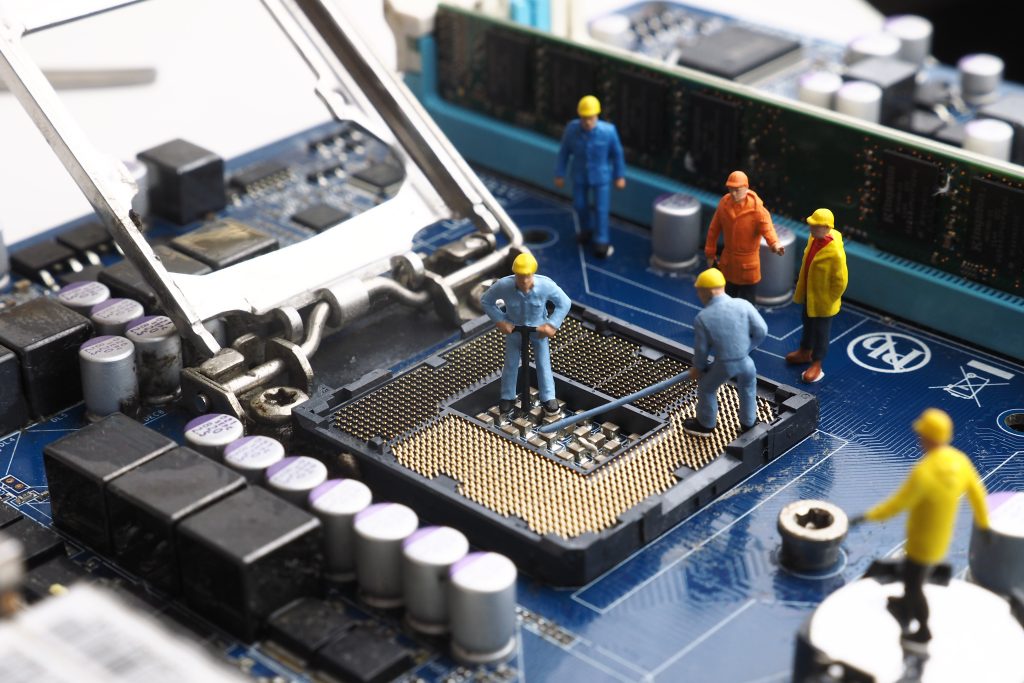

PROCESS ENGINEERING

Machining studies

Detailed studies of the machining process to provide a solution to the technical, production, quality and economic requirements established by the client.

Specialised machining cycles

Design and development of individual cycles for specific machining operations or inspection.

Design of tools and fixtures

Design and manufacture of specialised tools and fixtures thanks to our experience in machining and close collaboration with the main suppliers.

Machining tests

Machining tests to customers requirements (times, precision, consumption, etc.) at both the pre-sale and the pre-acceptance phases as well as at the final acceptance of the machine.

MAINTENANCE

Preventive maintenance

We have collaboration agreements for regularly checking machine status and for maintenance and repair of malfunctions according to an agreed framework of areas to check.

Machine levelling check and geometric alignment

To ensure that our equipment produces high quality components we carry out a complete check of the geometry using laser interferometer, ballbar, etc. and in the event of faults the necessary adjustments and compensations are made.

Head and measuring unit maintenance

Repair, maintenance and remodelling of heads and proprietary measuring units, including temporary replacement: we have replacement heads to minimise machine downtime.

ADVANCED TRAINING

The training we offer is specially geared towards operators to ensure efficient and correct use of the machine. Together with the operators we perform practical training on topics related to mechanics, fluids and electrics of the machine.

ADVANCED TRAINING FOR MACHINE USERS

Our on-line technical support team immediately understands the service requirements of the customers, ensuring high availability of equipment and thus minimizing maintenance costs.

DIAGNOSIS AND REMOTE SUPPORT

ONLINE SUPPORT

Custom training on work modes, programming, cycles and specific functions of the machine, compensation of drives, alarm messages, machine recovery instructions, instructions for preventive maintenance, etc.

We offer advanced courses in:

- operation and management

- CNC programming

- maintenance

UPGRADING OF SOFTWARE-HARDWARE

Hardware Update

Replacement of the original mechanical and electronic hardware of the machine to the state of the art equipment will bring in the advantages of the new equipment in terms of enhanced features, power and efficiency. CNC packages including drives and servo motors, operator panels, balancing units, absolute positioning systems, PCs, etc. as well as subassembly updates to the latest mechanical designs fall into this category.

Software Update

Update of custom machining and measuring software packages to the latest versions that include new features for machining options, customization, display, simulation and control options.

Update of Specific Machine Equipment

Replacement of measurement and handling equipment with latest generation versions for improving reliability, precision and consistency and including state of the art parts for avoiding obsolescence.

DIGITAL SERVICES

ADVANCED SERVICES TAILORED TO THE NEEDS OF THE DIGITAL INDUSTRY

- HMI – Human-machine interface– to improve the interrelationship man machine, through an environment that simplifies machine operation, includes support for programming and specialised machining cycles, facilitates the maintenance reducing down-times, and provides information on how to reduce power consumption.

- Data system, a set of services based on machine monitoring and Big Data to analyse the machining process and machine behaviour. You can use your tablet or mobile phone to check the status of the machine and, if necessary, optimise the process or anticipate possible failures.

- Intelligent components, devices integrated in the machine that, based on the information received from multiple sensors, act to improve the performance and precision of machines, optimise the process times, increase the lifespan of tools, etc.

From the ground up, Teko provides solutions to engineering challenges faced in many industries including oil & gas, mechanical, environmental, geotechnical, chemical and many others. Teko has a complete staff of Engineers and Sale Technicians to design and builds complete systems per specified requirements and for any application cost effectively and efficiently. On both small and large projects, our experienced professionals work closely with our clients to achieve success, on time and on budget. We can produce multiple custom systems, such as (but not limited to):

- Your custom machines

- Components

- Pumps

- Compressors

- Pressure test equipment

Design and Engineering

Teko offers a full range of design and engineering capabilities and services to support our customers’ needs for design-in components and custom-engineered solutions. We provide complete engineering support to ensure our quality products perform to the highest standards. Our global engineering team enables us to provide engineering and technical support from anywhere in the world. Our in-house knowledge of materials, RF, microwave, and power conversion expertise, coupled with our design and engineering capabilities make us an ideal vendor-of-choice for many applications.

Why Machining for Steel Forgings? Machining is the process of removing excess material and achieving exact dimensions as per the requirements. The process of machining converts the steel forged part into a fully finished and ready-to assemble component. Here our machining service can be separated into two parts, one is Rough Machining, and the other is Precision Machining. Rough machining mainly means some simple machining works done by machining equipment’s like drilling machine, milling machine, CNC lathes, and some other small machining equipment’s. For more accurate tolerances, precision machining will be required by CNC, which will charge you high machining cost for the high equipment cost and labour cost. So, our in-house machining service includes turning, milling, roll threading, cut threading, grinding, and die manufacturing.

Our Machining Service for Steel Forgings

Although our close die forging process can provide precision forgings for our customers, when it compares with steel casting, sometimes it is still only near net shape for its process limits. So, to provide our customers net shape or finished products, fly forge can supply value-added machining service after closed die forging. This will without doubt to help our customers to save time and do control quality better.

Advantages of Machining for Steel forgings in Our Company

- Equipped with all kinds of advanced machining equipment’s, such as CNC, milling machine, boring machine, drilling machine, etc. So, we can provide you finished products with different machining demands after forging.

- Mature machining technology. In our company, in addition to forging workshop, we have an individual machining workshop, which is operated by a strong engineer team. So, you will no need to source extra machining job once you cooperate with us.

- Machining cost & lead time can be saved. Our machining service is provided to offer our customers better service, so compare with some machining factories, our machining price will be quite competitive. Besides, the lead time can also be ensured if both forging and machining jobs are operated in the same company.

- Besides machining services, Teko Forge can supply other value-added services for steel forgings, such as in-house tooling, surface treatment, heat treatment etc

Teko Corporation has implemented a new policy regarding repairs. To have repairs received and evaluated in a timely manner we are asking you to complete our “Repair Return Form.” This will enable our technicians to better diagnose problems and repair your items more effectively. Make sure to include shipping information if the item is being sent via carrier. If items are customer drop off, please make sure the form is filled out prior to the drop off. With drop off items, please hand deliver the form to a Teko employee. Teko Corporation would like to thank you in advance for your cooperation.

Our specialists support the customer in the installation and commissioning of the production equipment – whether a new installation or an expansion – locally all over the world. On request we will undertake transportation, insurance, and installation, including monitoring and documentation. We install machinery, control equipment and complete systems on schedule by way of complete turnkey systems. We help during commissioning and optimise the machines in terms of the product quality and productivity demand. On-site approval is part of our scope of services as is in-depth training for operating staff. Furthermore, we will support the customer in the validation and approval of its systems by the relevant authorities. Ensuring the best possible production start.

Mechanical and electrical Commissioning

On request, we support the customer onsite in the mechanical and electrical commissioning. The mechanical part includes various process steps, amongst others the fitting of bowl, bowl insert and recirculation pipe. An essential task is the verification of the correct installation of the machine. The electrical commissioning includes the inspection of the cabinets, wiring and functionality of sensors and actuators. Furthermore, our service technicians make different settings for example for pressure transmitter and flow switches. This is followed by a test run of the machine, safety related function tests and communication tests as well as software and visualisation adaptions to requirements on site. Before the acceptance test and handover of the machine to the customer, our experts instruct the operating personnel.

Worldwide Logistics Services:Through our world class logistics support network, Teko provides a total supply chain solution to meet or exceed our customers’ expectations. No requirement is too big or too small. Some of the logistics services we provide our customers include:

- Same day shipments to domestic customers is provided when the stock order is received in our distribution centre as late as 6 p.m.

- 24/5 “on call” support

- Ship scheduling to meet JIT (Just-In-Time) or future planned need dates

- Consolidated shipments to domestic and international locations

- Special re-packaging

- Freight carrier coordination

- Consolidated order shipping

- Special product testing or acting as the 3rd party logistics provider

To learn more about our worldwide logistics services, visit our website